Super Therm® is a water-based coating (like paint), developed in conjunction with ceramic engineers from Marshall Space Center (NASA). Heavily tested, the product contains proprietary ceramics, resins, and a urethane that counteract the four methods of heat transfer: radiation; conduction; convection; and infrared. Super Therm® is a true performance coating with insulating properties and has the resistance equivalent to 8 inches of fiberglass.

As the only ceramic coating developed in cooperation with NASA, Super Therm® is the most effective, durable, and long lasting ceramic coating on the market.

The ceramics provide insulating effectiveness through uniformity, the resins provide flexibility, durability, and heat-resistance, and the urethane acts as a moisture barrier (along with being UV-resistant). This combination results in a coating that can reflect heat and fire, and withstand the elements for a number of decades.

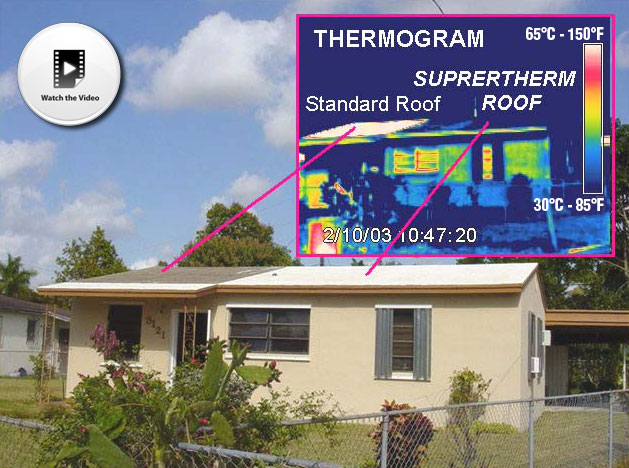

There is no limit to the application possibilities for Super Therm®. It can be used on metal roof structures such as warehouses, shipping containers, mobile homes, livestock barns, and grain bins; oil tanks; refrigeration units etc. Super Therm® can help reduce ambient temperature by as much as 20%. Depending on the application this translates into reduced heating and cooling costs, improved animal and plant life, greater storage protection, increased life expectancy for the structure itself and improved human comfort.

Super Therm® is a combination of high-performance, water-borne acrylic resins, which cures out completely in one week to an extremely tough, durable, non-yellowing, water-resistant coating that also provides flexibly and ultra-violet stability. Super Therm® offers toughness unmatched in the current market coupled with the flexibility necessary to meet the stresses of contraction and expansion without cracking or breaking down. This single development enables the coating to outlast all other insulation coating products-20 years or more from a single application (based on the use of recommending coating thickness and proper application methods). Other coatings will develop hairline cracks when the surface moves, through which moisture invades to develop blistering and finally peeling.

Super Therm’s flexibility and durability is accomplished through four different types of resins used in the foundation. Two acrylic resins blended together specifically for the purpose to achieve elasticity, adhesion, and provide a water resistance to ponding water. A urethane is blended in to provide a moisture barrier and bind all the resins together for added weatherability and UV-resistance. Finally, a special additive is blended into the resin mix to create a slower dry down to avoid any surface cracking due to our load of ceramic compounds, and to give a silky finish that enhances and extends the life of the coating in all climates due to its special polymers that guard against burn out. Super Therm® can also withstand exposure to -60°F (-51.1°C) without deterioration and, according to mil thickness, up to 1600°F (871.1°C).

Super Therm’s flexibility and durability is accomplished through four different types of resins used in the foundation. Two acrylic resins blended together specifically for the purpose to achieve elasticity, adhesion, and provide a water resistance to ponding water. A urethane is blended in to provide a moisture barrier and bind all the resins together for added weatherability and UV-resistance. Finally, a special additive is blended into the resin mix to create a slower dry down to avoid any surface cracking due to our load of ceramic compounds, and to give a silky finish that enhances and extends the life of the coating in all climates due to its special polymers that guard against burn out. Super Therm® can also withstand exposure to -60°F (-51.1°C) without deterioration and, according to mil thickness, up to 1600°F (871.1°C).

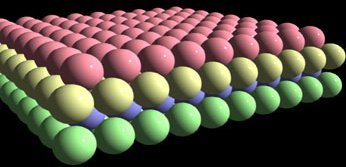

Here’s the secret: Super Therm® contains 4 specific ceramics that work together unlike any other product on the market – two are reflective for UV and visual light, one acts as a non-conductor for emissivity to stop heat load and the fourth blocks the infrared solar heat energy making it a high performance and effective energy friendly solution. With a Total Solar Reflectance of 96.1 out of 100 it’s supreme for fire prevention, mould prevention, moisture control and reduces sound.

Super Therm® was applied on a manufacturing facility in Kansas that was experiencing a great deal of difficulty in cooling various buildings of the factory due to variance in size and significant volume. The results were an immediate reduction by 12°F (6°C) on the lower levels, with an even greater reduction to the attic storage and overhead work zones on the second story. This temperature reduction enabled the facility to utilise simple ceiling fans for cooling during the summer months, and thereby lowering the overall expense of energy.

Looking to join one of the world’s leading coatings companies. Contact us if you’re a quality applicator looking for new products and markets!