Super Therm® weather resistive barrier, solves many of the challenges facing traditional house wrap and building paper. A fully-adhered system is the best insurance against water and air intrusion. Super Therm® is a fluid-applied, seamless protection for moisture sensitive structures in the event of a breach in exterior wall coverings. Super Therm® protects against ingress of incidental water such as that caused by severe weather, vapor or condensation, into the building or facility.

Super Therm® weather resistive barrier, solves many of the challenges facing traditional house wrap and building paper. A fully-adhered system is the best insurance against water and air intrusion. Super Therm® is a fluid-applied, seamless protection for moisture sensitive structures in the event of a breach in exterior wall coverings. Super Therm® protects against ingress of incidental water such as that caused by severe weather, vapor or condensation, into the building or facility.

Class A fire resistance for all walls or roofing it covers. ASTM E-84 is “0” flame spread and “0” smoke.

Class A fire resistance for all walls or roofing it covers. ASTM E-84 is “0” flame spread and “0” smoke.

Sound reduction through walls or roofing where Super Therm® is applied. ASTM E90 “Standard Method for Laboratory measurement of Airborne Sound Transmission Loss of building Partitions”, and ASTM E413 “Standard Classification for Determination of sound Transmission Class”. Sound Transmission Coefficient up to 50%.

Water Barrier protection to a 55mph wind driven rain. ASTM D 6904

Resistance to Wind Driven Rain for Exterior Coatings. ASTM D7088, Resistance to hydrostatic Pressure for Coatings.

Mould/Mildew Resistance. ASTM D3273-82T tested for severe mould environment – temperature 90°F (32°C) and RH of 95%-98% for 5 1/2 weeks. Rated 9 out of 10.

Insulation in terms of blocking heat load. In the field of insulation, the standard “R” (resistance) value is a measurement of how fast the heat will conduct or travel through the material…mostly fibreglass. Fibreglass insulation doesn’t block the heat. Once it is full it releases the heat into the structure. Super Therm® Insulation coating blocks 95% of solar heat and 99% of infra red heat therefore does not utilise the R value as there is no resistance.

Tampa Armature Works uses Super Therm® insulative coating, which is sprayed on both sides of the remaining container walls to prepare the house for heating and cooling loads. Super Therm® is a high-performance, four-part ceramic coating that carries an RE value of RE-19 and adheres to the steel surface of the shipping containers. “It really worked,” says Shannon Locklair, project superintendent for the North Charleston house. “We had an open house one day when it was 85 or 90 degrees out and the air was at least 10 to 20 degrees cooler inside. This was before we had even installed the windows.”

“The true key to insulation is preventing heat load,” says J.E. Pritchett, founder and developer of Super Therm®, a ceramic insulation coating. The concept is simple: Why use fiberglass insulation to slow the transfer of heat into a building when you can just prevent that heat from ever loading onto the building in the first place? If heat is kept off the structure to begin with, that fiberglass insulation becomes unnecessary. It’s a change in the way we think about insulating our homes against energy lost. “R rating is for the 20th century,” says Pritchett. “Emissivity is 21st century.”

Consumers should be careful to distinguish between purely reflective coatings and true insulating coatings. Reflective coatings only perform when clean and will not block all forms of heat, but a coating with insulative and reflective qualities will block more than one form of heat.” Super Therm® uses four ceramic compounds to block short-wave radiation, IR, and to block the conductivity of heat through the surface,” claims Pritchett. “It’s not just a reflective coating.”

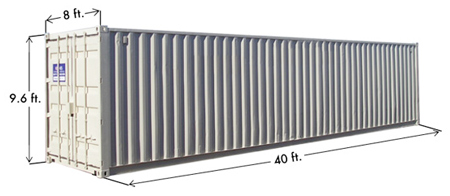

Each container has 2 sides / 2 ends and the roof

Currently we sell full 5 gallon US (18.9 litres) pails. We recommend using Super Therm® on the floor internally as this neutralises any contaminants in the timber and provides additional floor insulation. Super Therm® has a coverage of 40-45 m2 per pail depending on application.

Note: if container has rust it needs to be thoroughly cleaned and we suggest a coat of Rust Grip before you apply Super Therm®. For the ultimate protection then apply Enamo Grip over the top as the perfect protection against the elements.

Contact us below if you wish to purchase Super Therm® for your shipping container project.

This is the “resistance” factor. This depends on the “loading” of all the available heat and then checking how fast it conducts through the material. Problem with this technology is that the heat “is” transferring through and conducting into the house or facility at only a slower rate, but “is” transferring.

The Super Therm® blocks the initial HEAT LOAD which is the beginning of the heat transfer measurement. It is a fact, that if you “reduce the amount of heat in the initial loading, you have reduced the amount of heat “available” for transfer into the house or facility”.

Would it not be better to reduce the heat load rather than simply slow all the heat load down, which it all makes it through eventually. See the Texas Container test below pdf

Sardinia has a typical mediterranean climate. During the year there are approximately 300 days of sunshine, the average temperature is between 11 to 17°C (52° to 63°F), but in summer the extreme temperature gets up to 36°C (97°F), effectively a desert environment.

Two of the 3 corrugated-steel exteriors of the containers were painted with Super Therm®, a ceramic coating that insulates the structure to reduce heating and cooling loads. Super Therm® ceramic coating is a paint mixed with 4 ceramic compounds for application via spray or roller to exterior and interior surfaces. Ceramic coatings are measured by their emissivity – it measures both the ability to reflect heat and the amount of heat that is loaded onto a surface.

Although they installed air conditioning, they have never used it thanks to the Super Therm® insulation, if anything, the paint works almost too well, making the containers feel almost like refrigerators at night!

They bought 3 containers – 2 of them they painted with Super Therm®, they finished the paint and could not buy it on this island, so they used normal paint for the third container. The exposure to wind and sun has been the same for all three, all three had the same amount of doors for ventilation, but the ‘normal’ one which we used as bathroom, has been terribly hot by day and by night. The clients said this research might be too spontaneous and empirical, but this was what they have experienced so far.

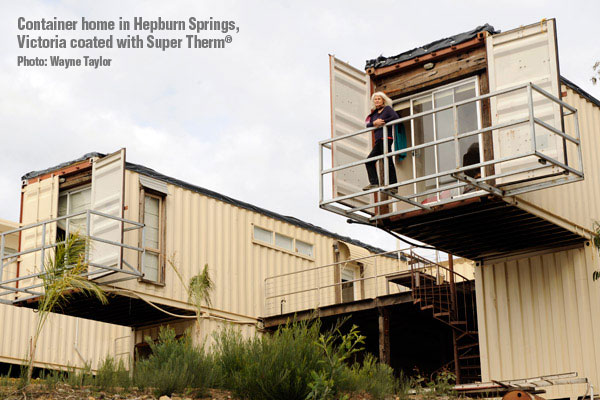

Madeleine McCristal surveys the surrounds from the Hepburn Springs home she is creating using 12 shipping containers coated with Super Therm® that provides insulation. See pdf of photos.

Looking to join one of the world’s leading coatings companies. Contact us if you’re a quality applicator looking for new products and markets!